MAKE A FRYNIUS DECISION

Robotize your Kitchen

Integrate Now - Plug & Fry instantly

FRYNIUS

The Turbine of the Gastro Revolution.

FRYNIUS is a robot fryer workstation that can be integrated into existing kitchens.

Whether it’s chicken wings, fries, nuggets, falafel, spring rolls, churros…, FRYNIUS is highly versatile and designed for the full range of international fried food concepts.

Perfect for anyone looking to enter the world of robotics quickly, efficiently and without compromising quality, crispiness, or fresh flavor.

FRYNIUS

FRYNIUS is a robot fryer workstation that can be integrated into existing kitchens.

Whether it’s chicken wings, fries, nuggets, falafel, spring rolls, churros…, FRYNIUS is highly versatile and designed for the full range of international fried food concepts.

Perfect for anyone looking to enter the world of robotics quickly, efficiently and without compromising quality, crispiness, or fresh flavor.

The Turbine of the Gastro Revolution.

Fried Food: A Shared Tradition Across All Cultures.

Let’s talk about how FRYNIUS adapts easily to global cuisines, helping you scale franchise concepts with maximum flexibility.

Fried Food: A Shared Tradition Across All Cultures.

Let’s talk about how FRYNIUS adapts easily to global cuisines, helping you scale franchise concepts with maximum flexibility.

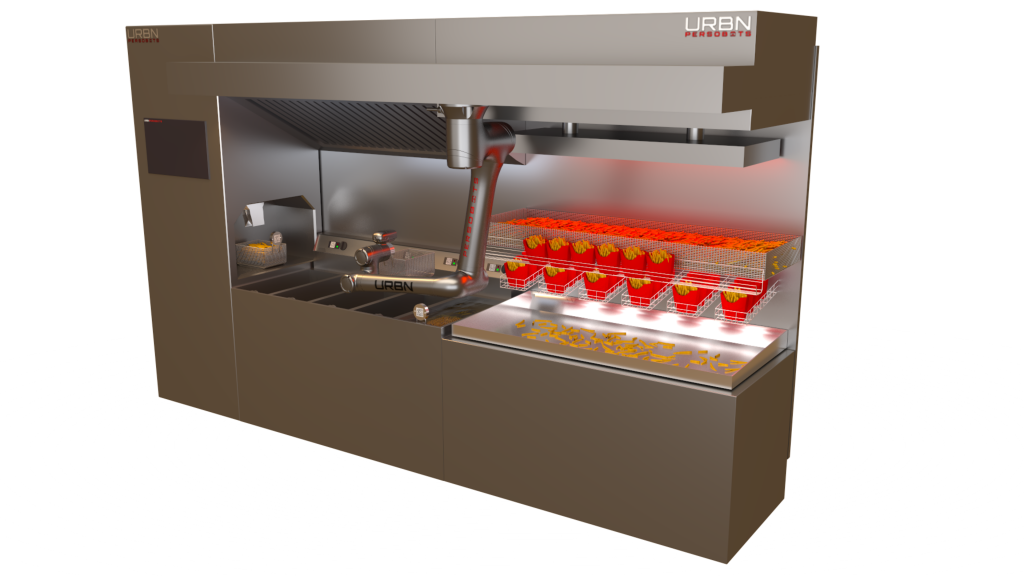

Meet your new FRYNIUS.

The Robot Fryer Workstation

PB-Core OS

PB-Core OS is the intelligent operating system for autonomous robot kitchens. It controls all core processes such as portioning, frying, packaging, and cleaning. Fully compatible with Siemens PLCs, food-safe, easy to maintain, and built for long-term, high-reliability operation.

PB Fryer

The fryer monitors oil level, oil level and oil quality in real time. Oil is automatically refilled and filtered when needed. For perfect frying timing, baskets are precisely lowered into and lifted out of the oil using an automated lift system.

Fanuc CRX10 Robot

The FANUC CRX-10iA is a world-leading 6-axis robot from Japan, known for its exceptional reliability and performance in demanding environments like robotic kitchens. Built for maximum functionality and stability, it offers up to 8 years of maintenance-free operation. FANUC also provides the most extensive and reliable service network worldwide.

PB Frozen Food Dispenser

The Frozen Food Dispenser is an industrial IoT-enabled freezer that communicates with a central kitchen control system: PB-Core OS. It automatically portions and releases frozen products into the fryer basket according to predefined recipes.

PB CRUNCH

PB CRUNCH is the intelligent holding station for crispy fried food. It keeps products warm, juicy, and crunchy using precise heat and air control. Managed by PB-Core OS, it ensures ideal serving temperature and texture, perfectly timed for human pick-up and packaging.

PB Industrial Kitchen Hood

The extraction hood filters up to 2,000 m³/h and uses a GUC 1214 E-filter with plasma technology. It removes odors efficiently. Motor function and air quality are continuously monitored by PB-Core OS. The system adjusts power as needed, saves energy, runs quietly and is easy to install.

PB-Core OS

The FANUC CRX-10iA is a world-leading 6-axis robot from Japan, known for its exceptional reliability and performance in demanding environments like robotic kitchens. Built for maximum functionality and stability, it offers up to 8 years of maintenance-free operation. FANUC also provides the most extensive and reliable service network worldwide.

PB Industrial Kitchen Hood

The extraction hood filters up to 2,000 m³/h and uses a GUC 1214 E-filter with plasma technology. It removes odors efficiently. Motor function and air quality are continuously monitored by PB-Core OS. The system adjusts power as needed, saves energy, runs quietly and is easy to install.

Fanuc CRX10 Robot

The FANUC CRX-10iA is a world-leading 6-axis robot from Japan, known for its exceptional reliability and performance in demanding environments like robotic kitchens. Built for maximum functionality and stability, it offers up to 8 years of maintenance-free operation. FANUC also provides the most extensive and reliable service network worldwide.

PB Frozen Food Dispenser

The Frozen Food Dispenser is an industrial IoT-enabled freezer that communicates with a central kitchen control system: PB–Core OS. It automatically portions and releases frozen products into the fryer basket according to predefined recipes.

PB Fryer

The fryer monitors oil level, oil level and oil quality in real time. Oil is automatically refilled and filtered when needed. For perfect frying timing, baskets are precisely lowered into and lifted out of the oil using an automated lift system.

PB CRUNCH

PB CRUNCH is the intelligent holding station for crispy fried food. It keeps products warm, juicy, and crunchy using precise heat and air control. Managed by PB-Core OS, it ensures ideal serving temperature and texture, perfectly timed for human pick-up and packaging.

FRYNIUS comes in 3 automation levels.

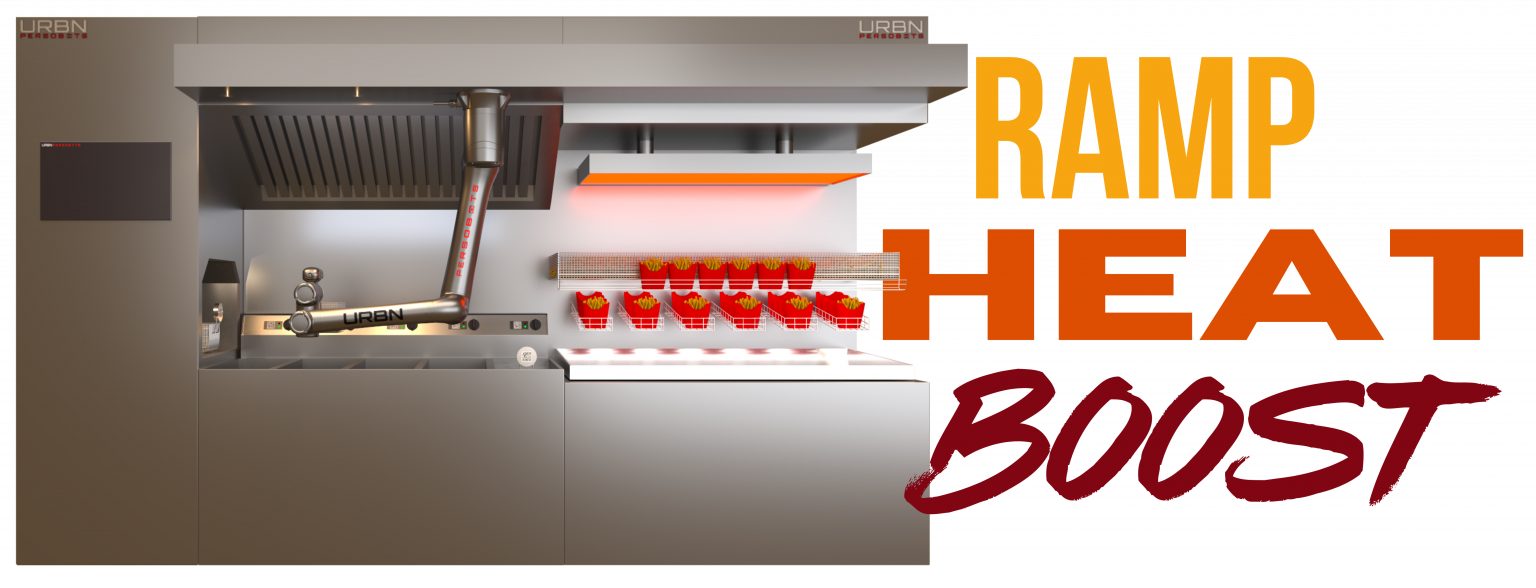

RAMP

The Entry into Robotic Frying

RAMP1 is designed for kitchens that work with frozen foods. With an automatic dispenser for frozen foods and a robotized frying workflow, RAMP1 takes over the heavy lifting. The fried products can either be held in the fryer or transferred into a heat-holding station.

OR

RAMP2 is the alternative for kitchens that rely on fresh ingredients and value handmade quality in their prep, but want robotic support during frying.

Fresh products are manually placed into the basket; from there, the system takes care of the rest, fully automated.

HEAT

HEAT unites fresh and frozen food frying in one robotic system.

This hybrid setup lets you run a mixed operation. Best for restaurant concepts with both deep-frozen favorites and freshly breaded items, all processed with robotic precision.

Whether it’s chicken wings from the freezer or hand-prepped vegetables. Both handled with seamless efficiency.

HEAT adapts perfectly to an advanced gastronomy menu including fried food. A single system that adapts to your menu, combining the reliability of frozen food workflows with the creativity of fresh ingredients. One kitchen. Twice the power.

BOOST

BOOST adds sauce and packaging automation for peak efficiency.

It is the ultimate enhancement of the FRYNIUS. By automating dispensing, frying, saucing and packaging, FRYNIUS BOOST eliminates four of the most chaotic manual steps in kitchen workflows. This reduces stress and manual workload for service staff, giving them more time to focus on what really matters: serving guests, maintaining quality, and keeping operations smooth.

It’s not just about saving time – it’s about reshaping roles and creating space for better hospitality.

Find the right FRYNIUS, tailored to your culinary concept.

Robot

IOT Fryer

Digital Ordering System

Frozen Food Dispeser

Freshly Breaded Food

Automatic Packaging

Automatic Sauce Dispenser

Show all features

Info Monitors

Manual Service Station

Vending Machine

Kiosk

Security System

Pick-Up Station

UQR Container

Robot

IOT Fryer

Digital Ordering System

Frozen Food Dispeser

Freshly Breaded Food

Automatic Packaging

Automatic Sauce Dispenser

Show all features

Info Monitors

Manual Service Station

Vending Machine

Kiosk

Security System

Pick-Up Station

UQR Container

Robot

IOT Fryer

Digital Ordering System

Frozen Food Dispeser

Freshly Breaded Food

Automatic Packaging

Automatic Sauce Dispenser

Show all features

Info Monitors

Manual Service Station

Vending Machine

Kiosk

Security System

Pick-Up Station

UQR Container

Robot

IOT Fryer

Digital Ordering System

Frozen Food Dispeser

Freshly Breaded Food

Automatic Packaging

Automatic Sauce Dispenser

Show all features

Info Monitors

Manual Service Station

Vending Machine

Kiosk

Security System

Pick-Up Station

UQR Container

Robot

IOT Fryer

Digital Ordering System

Frozen Food Dispeser

Freshly Breaded Food

Automatic Packaging

Automatic Sauce Dispenser

Show all features

Info Monitors

Manual Service Station

Vending Machine

Kiosk

Security System

Pick-Up Station

UQR Container

This isn’t just a product level logic – it’s a takeoff system.

RAMP

HEAT

BOOST

FRYNIUS RAMP

The Entry into Robotic Frying

RAMP1 is designed for kitchens that work with frozen foods. With an automatic dispenser for frozen foods and a robotized frying workflow, RAMP1 takes over the heavy lifting. The fried products can either be held in the fryer or transferred into a heat-holding station.

OR

RAMP2 is the alternative for kitchens that rely on fresh ingredients and value handmade quality in their prep, but want robotic support during frying.

Fresh products are manually placed into the basket; from there, the system takes care of the rest, fully automated.

FRYNIUS HEAT

HEAT unites fresh and frozen food frying in one robotic system.

This hybrid setup lets you run a mixed operation. Best for restaurant concepts with both deep-frozen favorites and freshly breaded items, all processed with robotic precision.

Whether it’s chicken wings from the freezer or hand-prepped vegetables. Both handled with seamless efficiency.

HEAT adapts perfectly to an advanced gastronomy menu including fried food. A single system that adapts to your menu, combining the reliability of frozen food workflows with the creativity of fresh ingredients. One kitchen. Twice the power.

FRYNIUS BOOST

BOOST adds sauce and packaging automation for peak efficiency.

It is the ultimate enhancement of the FRYNIUS. By automating dispensing, frying, saucing and packaging, FRYNIUS BOOST eliminates four of the most chaotic manual steps in kitchen workflows. This reduces stress and manual workload for service staff, giving them more time to focus on what really matters: serving guests, maintaining quality, and keeping operations smooth.

It’s not just about saving time – it’s about reshaping roles and creating space for better hospitality.